DTC Supply Chain Optimization: Technical Insights for Seamless Operations

Published: February 16, 2024 | Retail & Commerce

Direct-to-consumer (DTC) brands have emerged as e-commerce trailblazers, reshaping traditional retail paradigms by establishing direct connections with consumers through online platforms. The DTC model offers businesses unparalleled control over their brand experience, from product development to customer engagement. However, to thrive in this competitive arena, DTC brands must optimize their supply chain operations for seamless efficiency and scalability. In this comprehensive guide, we’ll delve deeper into the technical intricacies of DTC supply chain optimization, exploring advanced strategies and solutions tailored to the needs of technical users, e-commerce business owners, and industry professionals.

Understanding the DTC Supply Chain Landscape

To grasp the complexities of DTC supply-chain optimization, it’s essential to dissect the various components of this system. Unlike traditional retail models characterized by multi-tiered distribution channels, DTC brands exercise direct control over every stage of the supply chain, from production or sourcing to delivery. This holistic approach presents both opportunities and challenges, necessitating a nuanced understanding of each operational facet.

Key Components of DTC Supply Chain:

- Manufacturing or Sourcing: DTC brands often produce their goods in-house or collaborate closely with suppliers to maintain quality standards and reduce lead times. Leveraging technologies such as 3D printing or on-demand manufacturing can enhance agility and customization capabilities.

- Warehousing and Inventory Management: Central to the DTC supply chain is the efficient management of warehousing facilities and inventory levels. Implementing automated storage systems, such as vertical carousels or automated guided vehicles (AGVs), can optimize space utilization and minimize manual handling errors.

- Order Fulfillment: Timely and accurate order fulfillment is paramount in meeting customer expectations. DTC brands leverage advanced order management systems (OMS) and warehouse management systems (WMS) to orchestrate the seamless flow of orders from receipt to dispatch. Utilizing batch picking and wave picking methodologies can streamline operations and improve order accuracy.

- Last-Mile Delivery: The final frontier of the supply chain, last-mile delivery, poses unique challenges in terms of cost optimization and customer satisfaction. DTC brands employ route optimization algorithms and dynamic delivery scheduling tools to minimize delivery times and enhance the overall delivery experience. Additionally, partnerships with local courier services or the establishment of in-house delivery fleets can provide greater control over the last-mile process.

Overcoming Challenges in DTC Supply Chain Optimization

While the DTC model offers numerous advantages, it also presents formidable challenges that must be addressed through innovative solutions and strategic initiatives. From inventory management complexities to the intricacies of last-mile logistics, DTC brands must navigate a myriad of obstacles to ensure seamless operations and sustainable growth.

Challenges in DTC Supply Chain Optimization:

- Inventory Visibility and Accuracy: Maintaining real-time visibility into inventory levels across multiple channels is paramount for preventing stockouts and overstocking. Implementing RFID or barcode technology coupled with inventory management software can provide accurate inventory tracking and forecasting capabilities.

- Demand Volatility: DTC brands often face fluctuating demand patterns driven by seasonal trends, marketing campaigns, or external factors. Leveraging advanced analytics and machine learning algorithms, such as time series forecasting models, can improve demand forecasting accuracy and facilitate proactive inventory planning.

- Last-Mile Delivery Efficiency: The last mile accounts for a significant portion of overall logistics costs and can greatly impact customer satisfaction. Employing route optimization software, dynamic routing algorithms, and geofencing technology can minimize delivery times, reduce fuel consumption, and enhance delivery accuracy.

- Data Integration and Interoperability: Siloed data systems hinder collaboration and decision-making across the supply chain. DTC brands must prioritize the integration of disparate systems through robust API frameworks and middleware solutions, enabling seamless data exchange and interoperability.

Technical Solutions for Supply Chain Optimization

Innovations in technology have paved the way for transformative solutions that address the unique challenges faced by DTC brands in optimizing their supply chains. From AI-driven demand forecasting to robotic automation in warehouses, these technical advancements hold the key to unlocking operational efficiencies and driving competitive advantage.

Advanced Analytics and AI:

- Demand Sensing: By analyzing a diverse array of data sources, including historical sales data, social media trends, and market indicators, AI-powered demand sensing algorithms can anticipate shifts in consumer behaviour and adjust inventory levels accordingly.

- Dynamic Pricing Optimization: AI algorithms can optimize pricing strategies in real-time based on factors such as demand elasticity, competitor pricing, and customer segmentation, maximizing revenue and profitability.

- Predictive Maintenance: Leveraging IoT sensors and predictive analytics, DTC brands can proactively identify equipment failures and schedule maintenance interventions before costly disruptions occur. This predictive maintenance approach minimizes downtime, extends asset lifespan, and ensures operational continuity.

Warehouse Automation:

- Goods-to-Person Robotics: Autonomous robotic systems, such as automated storage and retrieval systems (AS/RS) and robotic pickers, dramatically reduce order fulfillment times by bringing items directly to warehouse personnel, eliminating the need for extensive manual travel.

- Automated Guided Vehicles (AGVs): AGVs navigate autonomously within warehouse environments, transporting goods between storage locations, picking stations, and shipping docks. These flexible and scalable automation solutions enhance warehouse throughput and operational agility.

- Vision Systems and Machine Learning: Integrated vision systems equipped with machine learning algorithms enable automated quality control inspections, defect detection, and SKU recognition, ensuring product accuracy and consistency.

Integration and Connectivity:

- Enterprise Integration Platforms (EIPs): EIPs facilitate seamless data exchange and interoperability between disparate systems and applications, enabling real-time visibility into supply chain processes and facilitating agile decision-making.

- Blockchain for Supply Chain Transparency: Blockchain technology provides an immutable and transparent ledger for tracking and tracing product movements throughout the supply chain. By recording transactions in a decentralized manner, blockchain enhances trust and accountability while mitigating the risk of counterfeiting and fraud.

- IoT-enabled Supply Chain Orchestration: IoT devices embedded within assets, vehicles, and inventory enable real-time monitoring of key metrics such as temperature, humidity, and location. This granular visibility enables proactive decision-making and ensures compliance with regulatory requirements.

Customer-Centric Solutions:

- Hyper-Personalization: Leveraging customer data and predictive analytics, DTC brands can deliver highly personalized shopping experiences tailored to individual preferences, browsing history, and demographic profiles.

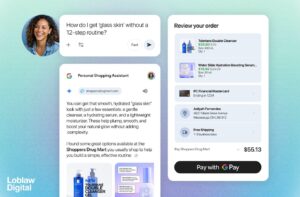

- Conversational Commerce: Integrating AI-powered chatbots and virtual assistants into e-commerce platforms enables seamless communication with customers, providing instant support, product recommendations, and order updates.

- Contactless Delivery and Pickup Options: In response to changing consumer preferences and health concerns, DTC brands are increasingly offering contactless delivery and pickup options, leveraging technologies such as QR codes, smart lockers, and autonomous delivery vehicles.

E-commerce supply-chain optimization is a strategic imperative for DTC brands seeking to remain competitive and resilient in the face of evolving consumer demands and market dynamics. By harnessing the power of advanced analytics, AI, automation, and customer-centric solutions, DTC brands can unlock new levels of efficiency, agility, and innovation across their supply chains. Embracing a holistic approach to optimization, grounded in technology and data-driven insights, will empower DTC brands to deliver exceptional experiences to their customers while driving sustainable growth and profitability in the digital era.

Connect with geekspeak Commerce to explore how our expertise in supply chain optimization can propel your DTC business to new heights of success.